CO2 Emissions - Production

The indicator for production CO2 is carbon intensity or CO2/tonne of concrete produced. Data from the energy use of concrete production and a proportional contribution from constituent materials are converted to carbon emissions using factors published by DEFRA with an adjustment for the process carbon emissions from cement.

The Standardised or Baseline mix is based on the average proportions of materials in concrete when the strategy was launched in 2008. By using these fixed mix proportions with each year’s carbon values, the industry reports the overall carbon intensity and shows the performance directly under its control.

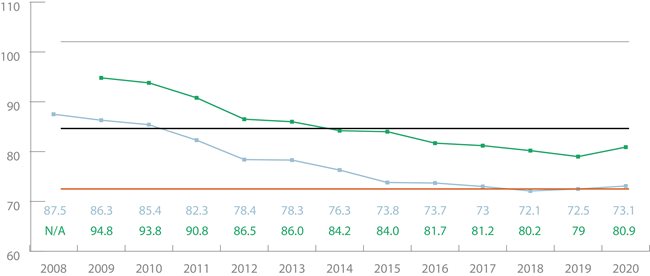

Performance indicator: CO2 emissions - Production (Standardised mix) (kg CO2/tonne)

2020 data shows that the 2020 carbon emissions target was met with CO2 emissions per tonne of 73.1 kg.

The target was to reduce CO2 emissions by 30% from the 1990 baseline equivalent to a value of 72.2 kg CO2/tonne of concrete produced. The 2020 data shows a reduction of 29.3% has been achieved.

For concrete + reinforcement the CO2 emissions are 80.9 kg CO2/tonne.

2020 Strategy Commitments

The concrete industry commitment to carbon reduction is to: Contribute to the delivery of a low carbon built environment.

Carbon emissions from the built environment arise from two main sources; ‘operational’ from using buildings and infrastructure and those ‘embodied’ in the manufacture of construction materials.

The concrete industry is fully committed to reducing the embodied carbon within concrete, and reports on carbon intensity - kg of CO2 per tonne of concrete produced and energy intensity in kWh/tonne. This data includes the emissions and energy use from the supply of constituent materials.

In addition, designers can influence the embodied carbon of concrete. The Concrete Centre provides guidance on how to reduce the embodied carbon of concrete, through online information and guidance documents including Specifying Sustainable Concrete.

Operational carbon from buildings is significantly greater than the embodied carbon in their construction materials. Concrete construction can make a significant contribution to reducing operational carbon through its unique combination of properties, in particular thermal mass. Guidance on the utilisation of thermal mass to reduce energy and carbon, and whole life carbon and buildings is available from The Concrete Centre.

The industry also has a commitment to: Provide Lifecycle Assessment data compliant with codes and standards.

Designers and specifiers need credible data to be able to quantitatively assess sustainable construction. Generic Environmental Product Declarations (EPDs) are available from the concrete industry, and proprietary EPDs are available from concrete manufacturers. An EPD, is a document that reports environmental data of products based on life cycle assessment (LCA) and other relevant information. Standards such as ISO 14025 and EN 15804 exist to ensure consistency of format and comparability of data. Read more from The Concrete Centre on EPDs.