Waste Minimisation

The indicator for waste minimisation relates to waste disposed to landfill per tonne of concrete production and includes waste related to the constituent materials attributed by their proportion in the concrete.

The second indicator is a net waste consumption ratio, this gives an overall indicator for the industry's use of waste and by products relative to its own waste to landfill. As the indicator shows the concrete industry is a consumer of waste.

Within the waste minimisation section the replacement of fossil fuels is also reported. The indicator is for the percentage of total energy use from the fuel source of material diverted from a waste stream.

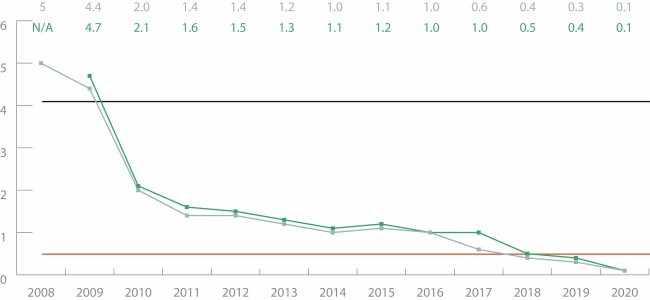

Performance indicator: Waste to landfill as a proportion of production output (kg/tonne)

In 2020, 100g (or 0.1kg) of waste went to landfill per tonne of concrete produced.

This has met and exceeded the 2020 target of a 90% reduction from the 2008 baseline, equivalent to 500g (0.5kg) of waste per tonne of concrete produced. The industry has made significiant progress on the longer-term aspiration for zero waste to landfill.

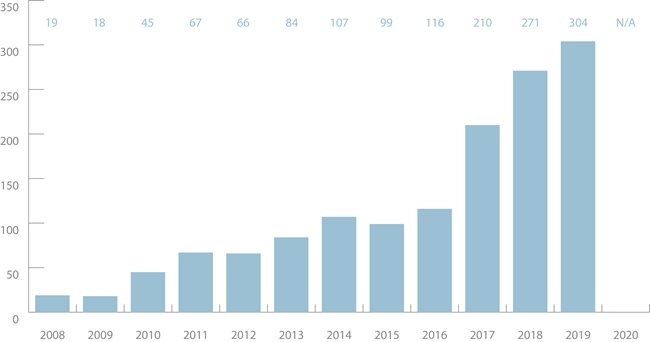

Performance indicator: Net waste consumption ratio

Due to the increasingly low amounts of waste sent to landfill, the net waste ratio was 881. This indicator has proven that the concrete sector is a net consumer of waste, and has minimised its waste to landfill.

Alternative metrics are now being considered.

The net waste consumption ratio gives an overall indicator for the industry's use of waste and by products relative to its own waste to landfill. This ratio is calculated by dividing the amount and waste and by-products used in concrete manufacture plus the materials diverted from the waste stream for use as fuels by the amount of waste to landfill generated by concrete production and its constituent materials.

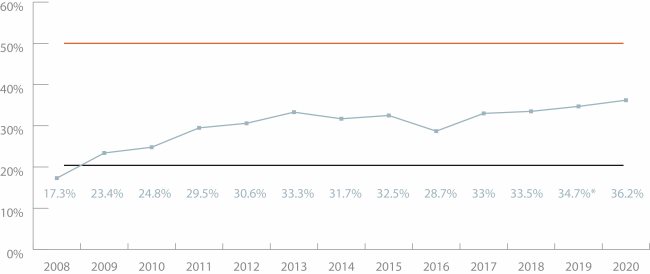

Performance indicator: Material diverted from the waste stream for use as a fuel source, as a percentage of total energy use

In 2020, 36.2% of total energy use for the concrete sector was from waste-derived fuels which is the highest value recorded since the strategy was launched in 2008.

The performance of the cement sector leads this indicator and here 46.8% of fuel comprised waste material.

The industry requires high temperatures for production, primarily in cement manufacture, and this is an opportunity to safely utilise alternative combustible materials as fuel instead of non-renewable fossil fuels. Where fuels used are recognised as carbon neutral under EU Emissions Trading Scheme (EU ETS), this has the additional benefit of reducing the embodied carbon of cement.

2020 Strategy Commitment

The 2020 strategy commitment is to: Develop a Material and Resource Efficiency Programme to inform best practice across the life cycle of concrete in the built environment. Read more